50-year coated and 316 stainless hardware

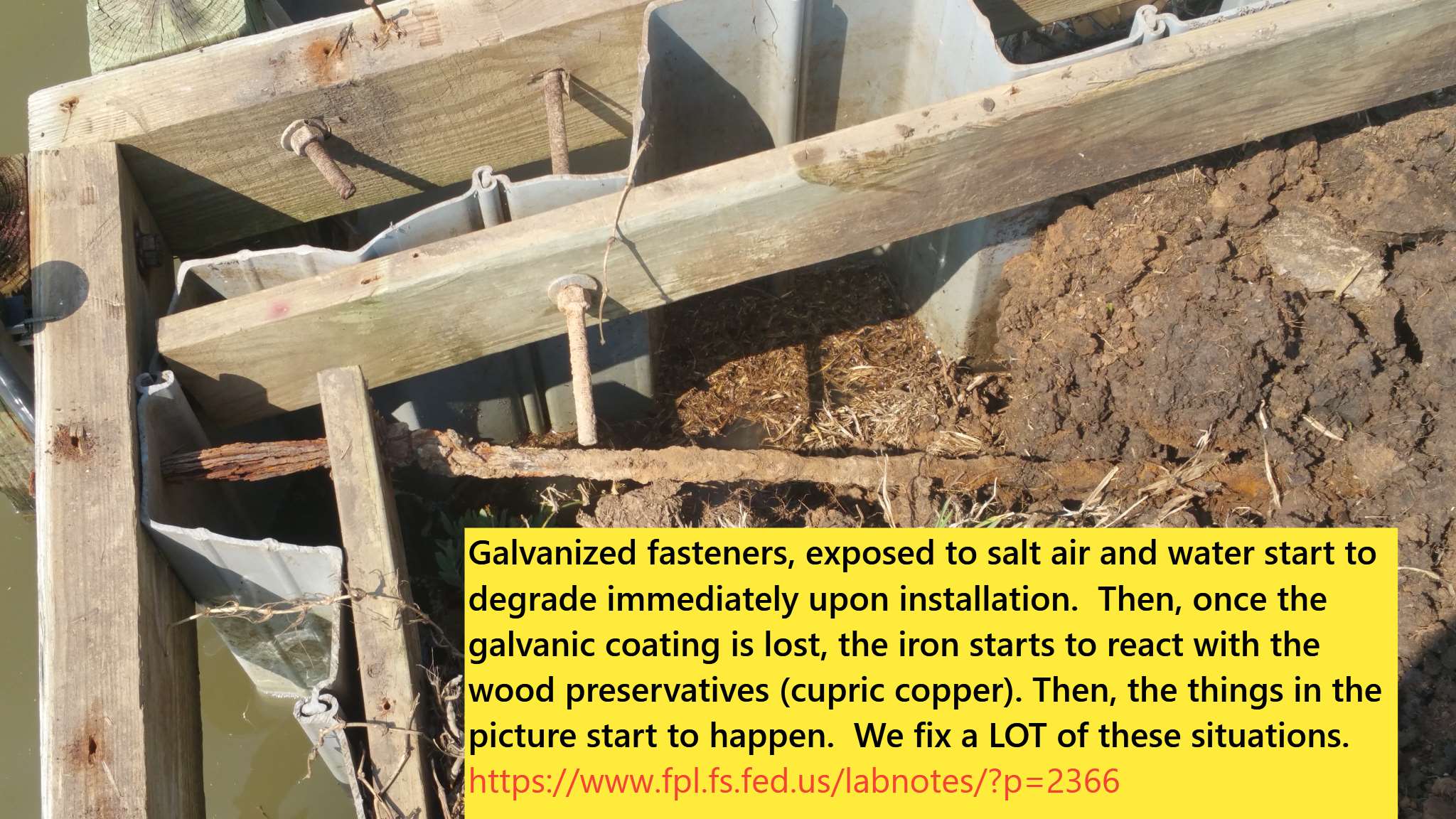

50-year coated and 316 stainless hardware When it comes to bulkhead construction and repair, it’s important to use high-quality materials that can withstand the harsh conditions of a waterfront environment. Unfortunately, many bulkheads fail due to the use of subpar materials or improper construction techniques.

At our company, we only use the highest quality materials and techniques to ensure that our bulkheads are durable, long-lasting, and can withstand the test of time. One of the main reasons why we use 50-year coated and 316 stainless hardware is their exceptional resistance to corrosion. Bulkheads are constantly exposed to water, which can cause corrosion and rust to develop on the materials used.

Over time, this can weaken the bulkhead’s structure and eventually lead to failure. By using high-quality materials such as 50-year coated and 316 stainless hardware, we ensure that our bulkheads are protected from corrosion and can withstand the harsh conditions of a waterfront environment. Additionally, using 50-year coated and 316 stainless hardware helps to reduce maintenance and repair costs over time.

These materials require less maintenance and repair work than subpar materials, which can save our clients both time and money in the long run. At our company, we understand the importance of using high-quality materials and techniques to ensure that our clients’ bulkheads are constructed or repaired to the highest standard.

We take great care to use only the best materials and techniques available to ensure the success and longevity of our projects. Contact us today to learn more about how we can help with your bulkhead construction or repair needs.